ACCI provides a wide variety of products the products listed below are specifically manufactured by ACCI.

All-In-One ER Probe / Coupon Test Station

Multi-function cathodic protection test station

Accurate Corrosion Control, Inc. has redesigned the “ALL-IN-ONE” ER Probe/Coupon test station. All-In-One test station allows complete corrosion monitoring. Flexible design allows multiple configurations in a durable self contained test station.

Test Station Features

Test Station Features

Want more information?

DownloadsPole Mounted Solanode™

The SolAnode™ is the solution for CP current in urban areas. It has a small footprint, requires no AC service drop, and is simple to install. For smaller CP power requirements, we offer a standard size pole and cabinet system which expedites delivery, installation, and reduces cost (larger outputs are available in other configurations).

Solanode™ Advantages

- Professional design and sizing for reliability

- Minimal installation footprint

- Theft resistant design

- Ready for installation

- Top quality components

- No AC power required

- Complete solar CP system

- 3 – 5 day battery backup options

- Touch safe terminals

Configurations (Based on noncoastal southwest USA sun exposure):

- 15w DC output

- 30w DC output

- 50w DC output

Features

- Theft resistant and DOT compliant pole, base and cabinet

- CP controller with multiple modes of operation and built in logging capability

- Remote monitoring available

Want more information?

Downloads

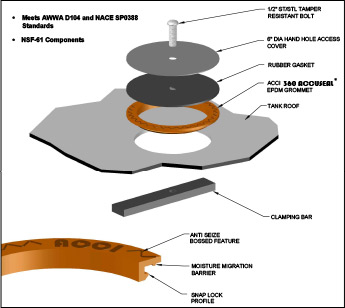

The 360 Accuseal

The 360 Accuseal is a specialized sealed hand hole grommet designed specifically for potable water tanks that utilize topload cathodic protection systems. Let’s break down its key features:

- Sealing Function:

- The Accuseal effectively seals the hand hole, creating a barrier against external environmental contaminants.

- Its raised edge ensures a secure and mess-free application during installation.

- Cathodic Protection:

- This component plays a critical role in cathodic protection inspections, services, or installations.

- By preventing corrosion in metal structures (including water tanks), it contributes to the longevity and reliability of the tank.

- Quick Installation:

- The 360 Accuseal is engineered for swift and efficient installation, minimizing downtime and disruptions.

- This feature is particularly valuable for ensuring a clean water supply.

Remember, the 360 Accuseal’s reliable seal and corrosion prevention significantly contribute to the overall functionality and longevity of potable water tanks.

Want more information?

DownloadsMeet NotHot™

NotHot™ Cold Silver Solder

Introducing NotHot™ Cold Silver Solder Attachment. A “No Heat” Method of Test Lead Wire Attachment; this alternative method of pipeline wire attachment consists of a pre-manufactured metal saddle constructed with a factory attached silver soldered wire and embedded neodymium magnet. Combined with the Conductive epoxy The NotHot™ Creates a connection to the pipe after the curing prosses.

This is a method of attaching wires to a buried metal pipeline without using typical methods that generate heat on the pipeline during wire attachment. There is a need to have an alternative to thermo-welding or brazing in specific instances when use of heat related wire attachment is unsafe or undesirable.

Watch How It Works!

Learn More

DownloadsCorr-Disc: Formally the (ACCI Engineered Coupon)

Key features:

PRCI Catalog No. PR-405-163602-R01 and ISO 22426-2020 compliant

Replicates pipeline coating defects

Each coupon is serialized for traceability

The ACCI Engineered Corrosion Coupons meet all the PRCI Catalog No. PR-405-163602-R01 and ISO 22426 design criteria requirements with regards to replicating and mimicking the similar pipeline coating, pipeline wall thickness (carrier plate) and steel grade with regards to a similar 1cm2 defect located on a buried/submerged pipeline. These state-of-the-art ACCI Engineered Corrosion Coupons, enable owner/operators to accurately measure the AC and DC potentials and AC and DC current densities in line with AMPP SP 21424 permitting the most realistic and accurate assessment of the combined effects of the CP and AC. The ACCI Engineered Corrosion Coupons ensures that a similar spread resistance, geometry, and dimension are created that best replicate a similar 1cm2 pipeline coating defect (or other engineered defect replicating the pipeline defects dimensions).

| Specifications | |

| Wire Type | 12 AWG XLP/USE-2/RHH/RHW-2 (Direct Burial) |

| Wire Length | 2 leads at 25’ (Standard, options available) |

| Coupon Diameter | 3 inches (Standard) |

| Coupon Thickness | 0.5” (Standard) |

| Coupon Steel Type | Low Alloy Carbon Steel (or specified to order) |

| Coupon Coating | Fusion Bonded Epoxy (FBE) (or specified coating) |

| Coating Anomaly Dimensions | 1.13cm (0.4449”) Diameter (1cm2 NACE SP21424) |

| Coating Thickness | ±20 mils (Typical or to order) |

| Casing Material | PVC |

| Potting Material | Black Encapsulating Compound |

| Connection Resistance | 0.001Ω (Max) |